With the improvement of people's living standards, people's requirements for the living environment are also increasing. In recent years, with the great development of the automotive industry, the problem of automobile pollution has become increasingly prominent.

In the production process, the major manufacturers have improved under the strict control of the national environmental protection department. In recent years, with the increasing control of environmental protection by the state, the after-sales protection of automobiles has also been included in the daily supervision of the automotive environment. It is extremely urgent to improve the automobile sheet metal process in time.

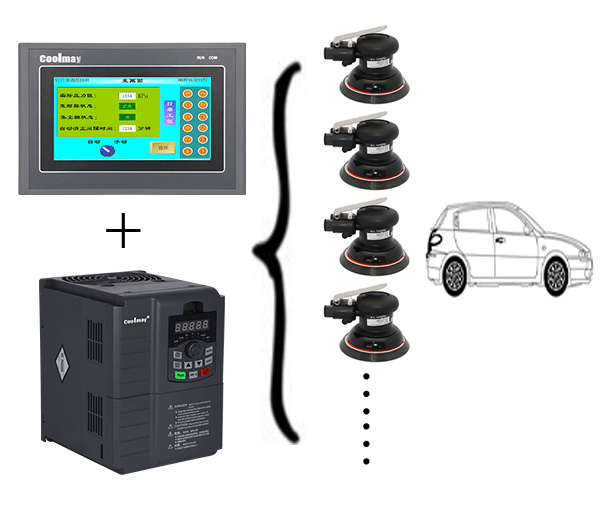

This control system plays an important role in the after-sales dust collection process. The system applied Coolmay HMI/PLC all-in-one EX3G-70KHA-44MT-2AD2DA-A4-A0, and Coolmay VFD CM540-7.5K.

I. Introduction

In the sheet metal process, the dust collection is required. Regarding the impact of the automotive sheet metal painting process on the environment, it is important to improve the sanding dust treatment equipment in time.

Coolmay has launched a control system for collections of grinding dust.

In the automotive sheet metal process,

the spray painting construction process --- the putty scraping process double --- the component midway primer process --- the topcoat spraying process --- the polishing process.

The system applied Coolmay HMI/PLC all-in-one EX3G-70KHA-44MT-2AD2DA-A4-A0, and Coolmay VFD CM540-7.5K.

This control system is mainly used in the after-sales guarantee of automobiles. It is a high-performance environmental protection equipment for the dust collection to reduce the impact on the surrounding environment.

The system is divided into main control cabinet and station parts.

II. Functions

This system mainly integrates the relevant action logic of the control system through PLC and HMI. This system has several major functions compared with the traditional system.

1. Applied Coolmay touchscreen HMI/PLC all-in-one, realized all functions, optimized the wiring process and simplified the troubleshooting process. The external power supply ensures the reliability of the all-in-one power supply to the greatest extent.

2. Applied the PID algorithm of PLC to control the VFD. On the basis of energy saving and environmental protection, the occurrence of bad power consumption is minimized.

3. The control process flow is optimized to achieve automatic standby while low station usage, and the power output is increased while high station usage, so that an automatic power management is realized.

III. Applications

During the after-sales maintenance process of the automobile, the grinding process of the automobile sheet metal is generated, and the system issues a command to the grinding machine to polish and collect the dust generated by the grinding process, thereby reducing damage to the environment and the human body caused by the dust.

IV. Summary

1. PLC PID algorithm (supporting self-tuning) can quickly and flexibly adjust the working condition of the VFD, and the frequency control is flexible, suitable for different places.

2. Automatic energy management to maximize the matching of practical power and reduce power waste.

3. Coolmay brand HMI/PLC all-in-one and VFD are used to optimize the after-sales service while reducing the production cost, so that all the faults can be quickly processed and the function requirements are updated in time.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved